THE PROCESS

-

Design Language & Style

Every interior is tailored to the soul of the car. We collaborate with customers on seating choices, cupholders, charging options, and finishes — all while keeping true to our clean, tight design style.

-

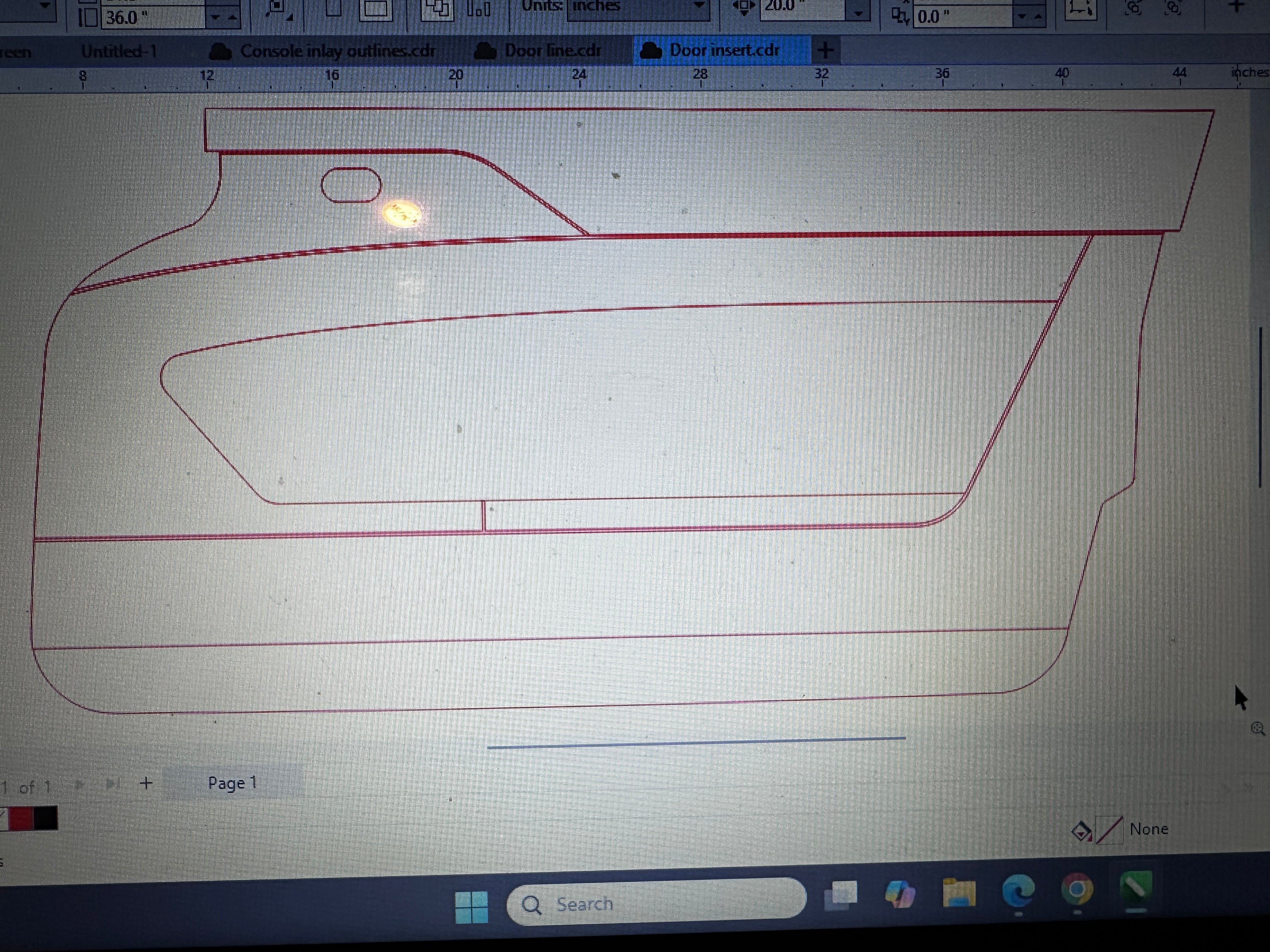

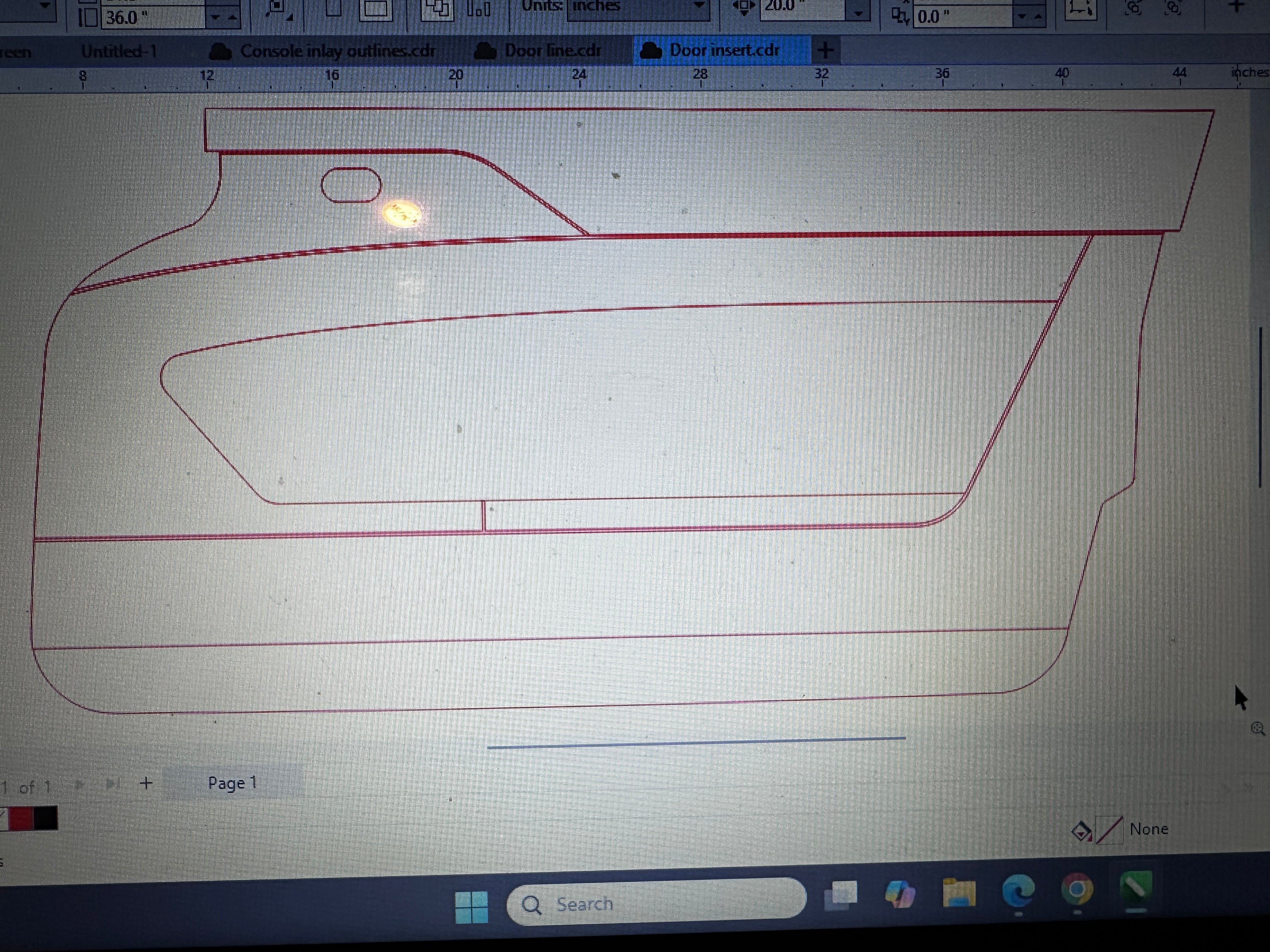

Sketch & Line Art

We start with line art — photographing the panel or interior, then sketching multiple variations and styles. This stage is about exploring ideas and refining the vision.

-

Digital Precision

Once the design direction is set, dimensions are transferred into 2D CAD. Every allowance for leather wrap, trim, and fitment is accounted for in the drawing, ensuring perfection before fabrication.

-

Bringing Designs to Life

From CAD, we move into fabrication. Depending on complexity, layers are laser cut, CNC machined, or developed into 3D models. We can even 3D print prototype parts to refine details before final machining.

-

The Foundation

Most of our panels are built from precision-cut .063" aluminum. Design layers are crafted from advanced composites and attached with machine screws, creating a strong foundation for everything that follows.

-

The Result

When everything comes together, the transformation is undeniable. A one-of-a-kind interior, seamlessly integrated, with every contour and stitch tailored to the client’s vision.